The contemporary situation is characterized by the advent of a sharing economy “sharing economy” which arises after the concept of “possession” enters the crisis. Possession therefore gives way to use, thus creating the transition from product to service, and back from ownership to access. “Biss” aims to deepen social design by developing circular economy logics, through the use of metal as project material and through the application of the sharing economy as a business model. The founding principle of the design motivations starts from an in-depth analysis of the current social context: a liquid society, as the philosopher Zygmunt Bauman defines, in which the concept of community has entered into crisis and has lost its meaning; over it prevails that of unbridled individualism, where no one is a companion on the road but antagonist of each, to be feared.

The name Biss enclose different meanings and characters of the project:

– biss, acronym for being inside the sharing society, is intended as an exhortation to move towards this sharing society, since the system conceived adopts the sharing economy as a business model;

– bis, recalls the concept of repetition that can be found in the circular system

conceived and in the reconfigurability of the designed products;

– finally bis is also associated with the prison world, since it refers to the regime

special custodial under Article 41 bis.

Through the analysis of the process and production possibilities, characterizing the prison laboratory under consideration, a circular system was designed and conceived to connect different actors and phases (design, production, delivery, use and re-invoicing), pursuing the founding principles of sustainability.

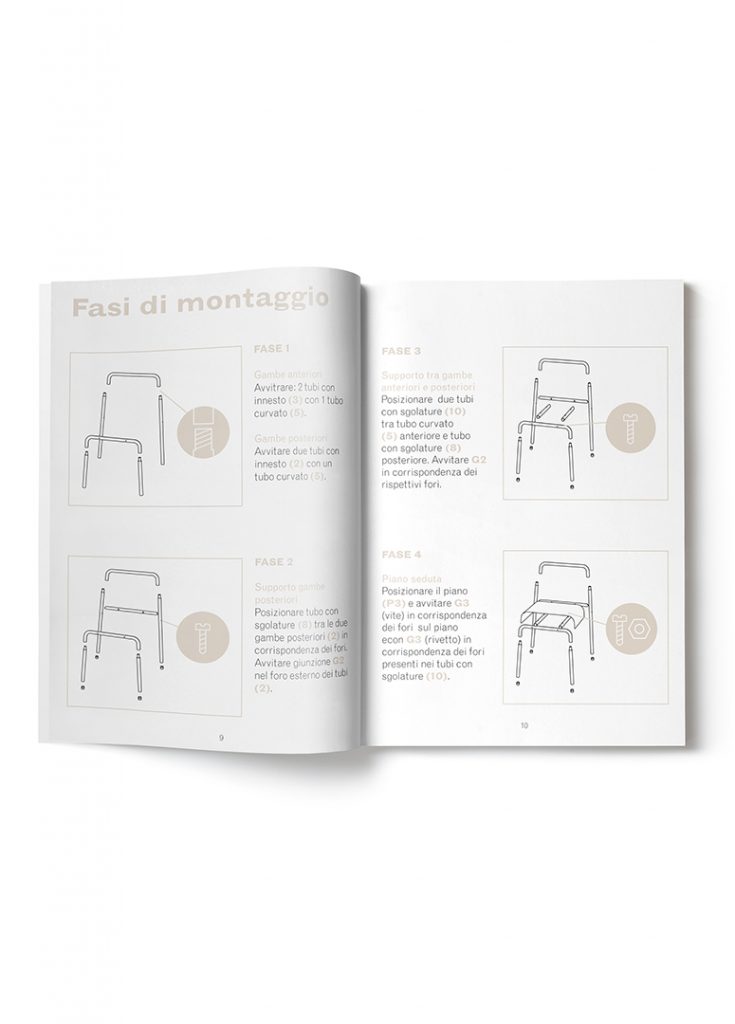

The designer, intended as a connector, has the role of designing the products, the technical data sheets, an instruction manual, the packaging in which they will be shipped, a digital platform that allows the rental of products.

The prisoners, after receiving the projects from the designer, will take care of the production, repair and packaging, storage of the products and subsequent re-invoicing.

The prison laboratory is intended as a place of production, re-billing, warehouse and therefore for managing orders and product returns.

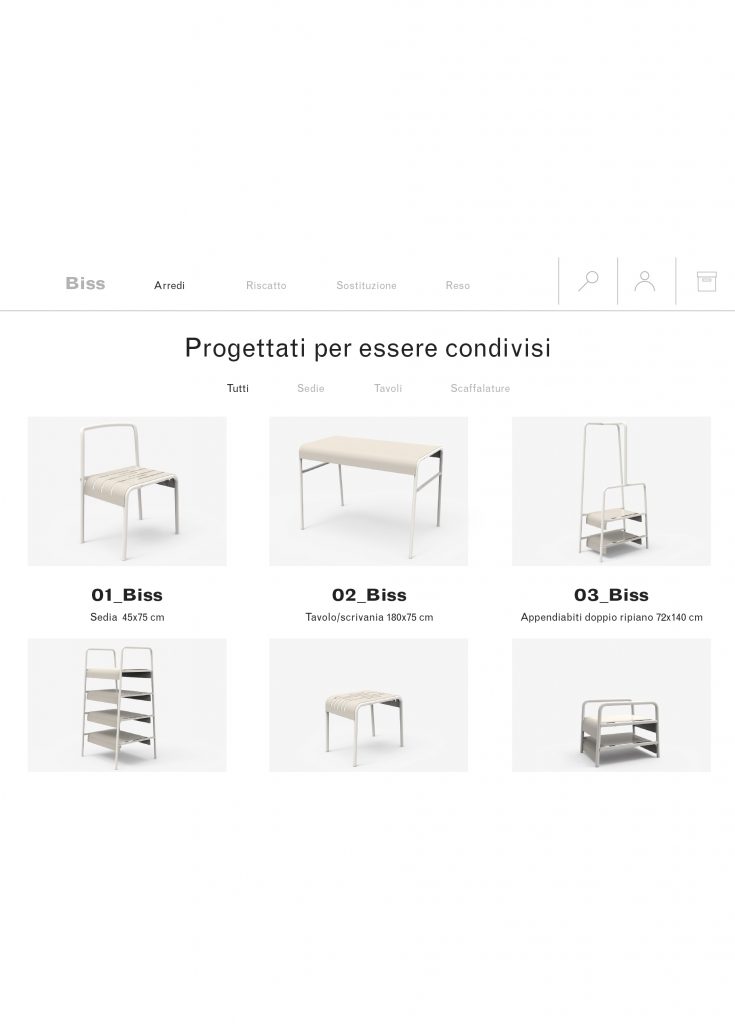

The means of communication for the generation of orders and returns, which will be carried out by the user, will consist of the digital platform.

Once the order has been generated, we will move on to the distribution stage, or the goods delivery and collection phase which will take place at the hands of specialized operators in the field of delivery and logistics or through the support of points of sale of goods made within others penitentiary institutions.

The goods will be delivered to the user, who can choose to self-assemble the product or products ordered, use them for the desired time and once the “rental” period is over, they can choose whether to redeem them, reconfigure them and then order other pieces or return them.

In the event that you decide to return, you will go through the phase of collecting the goods in order to be subsequently redistributed to the prison. Once returned to prison, the products will be remanufactured and regenerated for the purpose of a new use. All this was designed to be repeated over and over again.

Consider that the total number of Italian prisons is 190 institutions and 60,439 inmates present, almost every Italian city has at least one institution, but only 17,000 inmates have a job.

If these data from a certain point of view are striking, because it means that a large part of the prison population does not perform duties, on the other hand they are interesting to understand how important it is to undertake projects of this type.

The system currently provides for the production part in collaboration with the La Spezia prison, since it is personally known and with which previous collaborations had been activated, also because it has an excellent metal carpentry workshop. However, the system was designed to be scalable and therefore applicable to other existing prisons, in order to become a 0 km system.

Biss is therefore a project that takes into account the experience in the furniture sector and the production simplicity of the prison laboratory, with the aim of producing different furnishings for domestic use, designed for those people who for work, study or other needs define themselves as traveling.

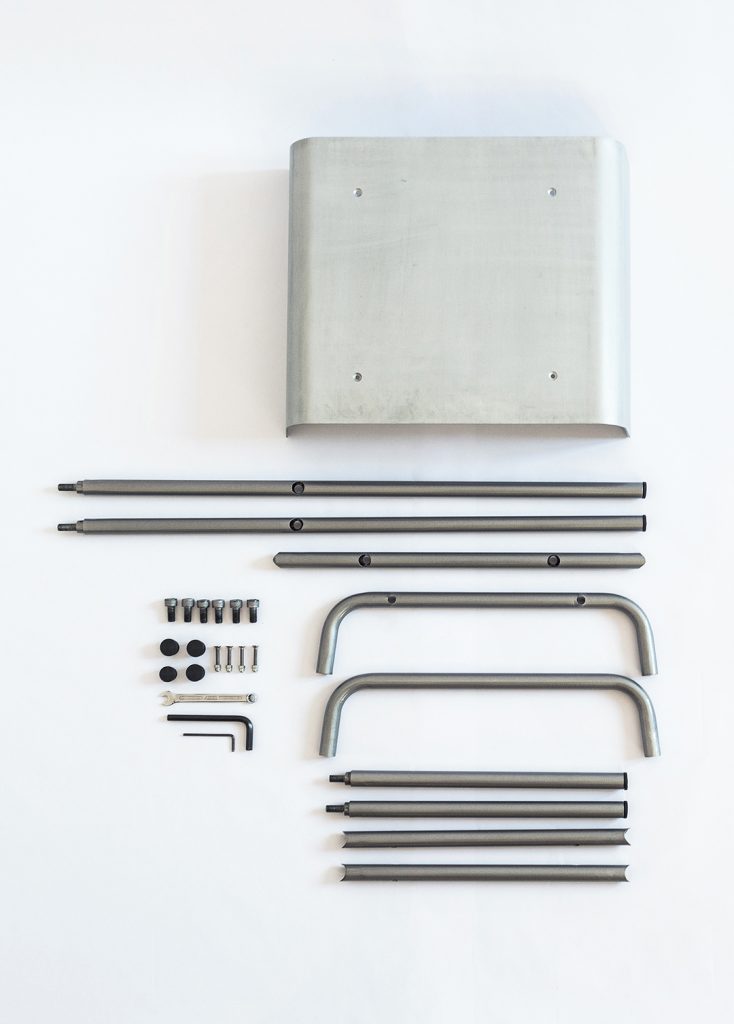

These products are made through the use of modular structural elements, tops, joints and couplings.

The products can be rented and / or subsequently purchased through a digital platform, able to manage orders and deliveries and monitor the life cycle of the products, from the time of shipment to their return, when they will be returned to the place. of production in order to be remanufactured, regenerated and subsequently reconfigured to be reused.

At the moment, a chair, a table (desk), a bookcase and a stender (clothes hanger) have been designed and prototyped in the laboratory.

The products have been designed according to the principles of modularity, characterized by a metal tubular structure, which can be completely disassembled and reconfigured.

For this reason, it was decided to eliminate welding as a process and to exploit other types of joints that metal offers, such as the thread of the tubular, the use of screws, grains and rivets.

The furnishings communicate with each other as they consist of the same structural elements that differ in length and width. The dimensions have been calculated for modules, 1, 1/2, 1/3 (the largest piece will be 3 times larger than the smallest piece) and therefore once damaged it can be reconfigured as a subsequent piece.

By exploiting the potential and strength of the metal material, the versatility of the products and their structures, a very wide range of products can be created by means of the assembly process of the modular elements. The structural elements consist of 10 pieces, each of them can be used for multiple products. In order for the production system to be easily scalable to multiple situations, a real instruction manual has been designed capable of guiding production step by step.